The Quickscan is an ideal instrument to increase quality, improve efficiency and reduce failure costs.

And after all, a good final product costs less in its entirety, provides a better workflow and results in a satisfied customer.

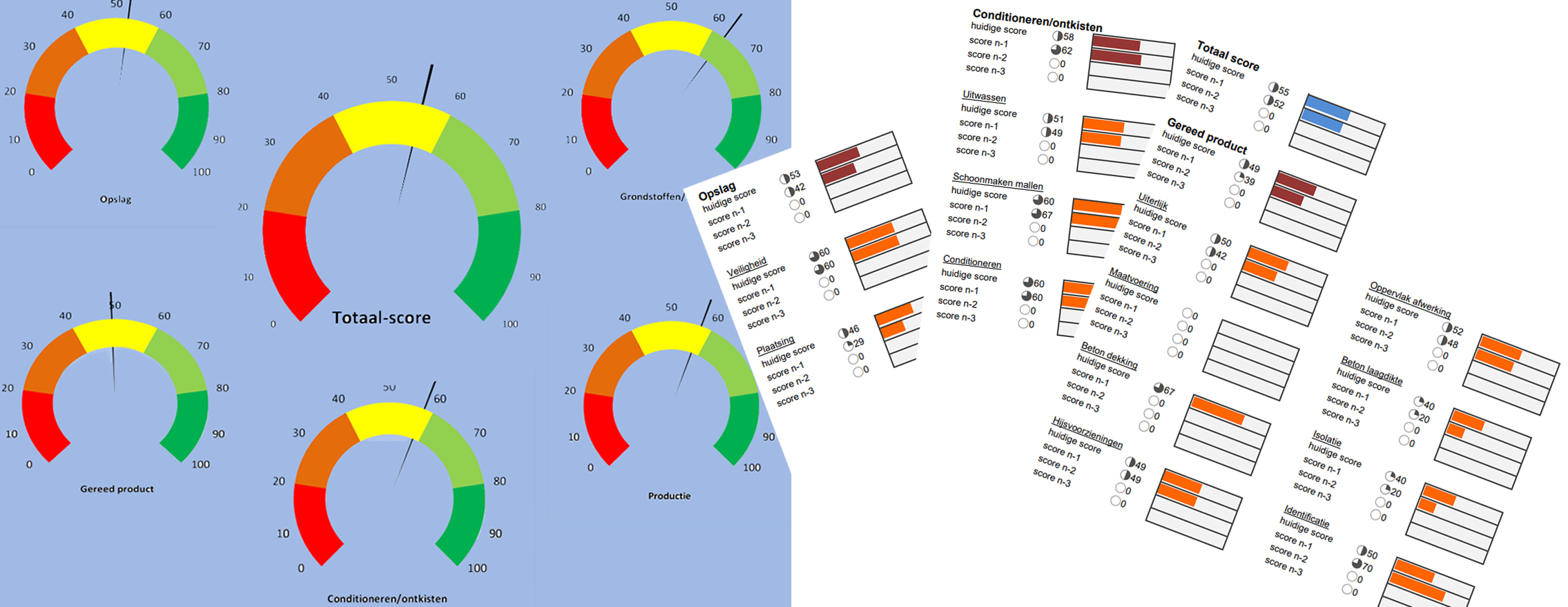

A Quickscan can be performed once as a snapshot, but is particularly suitable for periodically monitoring the quality improvement in a specified period. If desired, safety, sustainability, circularity, energy consumption, or CO2 production can also be assessed additionally.

Benefits

- The Quickscan simply takes place during production (working hours)

- By working together you make use of more than 30 years of experience in the precast concrete industry

- Workable advice that can quickly result in quality improvement, process optimization and cost reduction.

- Exploiting the synergy effect (concrete technology, production processes, quality systems and product requirements)

- Communication for and at every level

- The performance of your production process becomes measurable, so that adjustments can be made concrete and measured.

- Problems can be dealt with quickly and usually easily

- Save costs

- Possible periodic check for insight into progress and/or benchmark

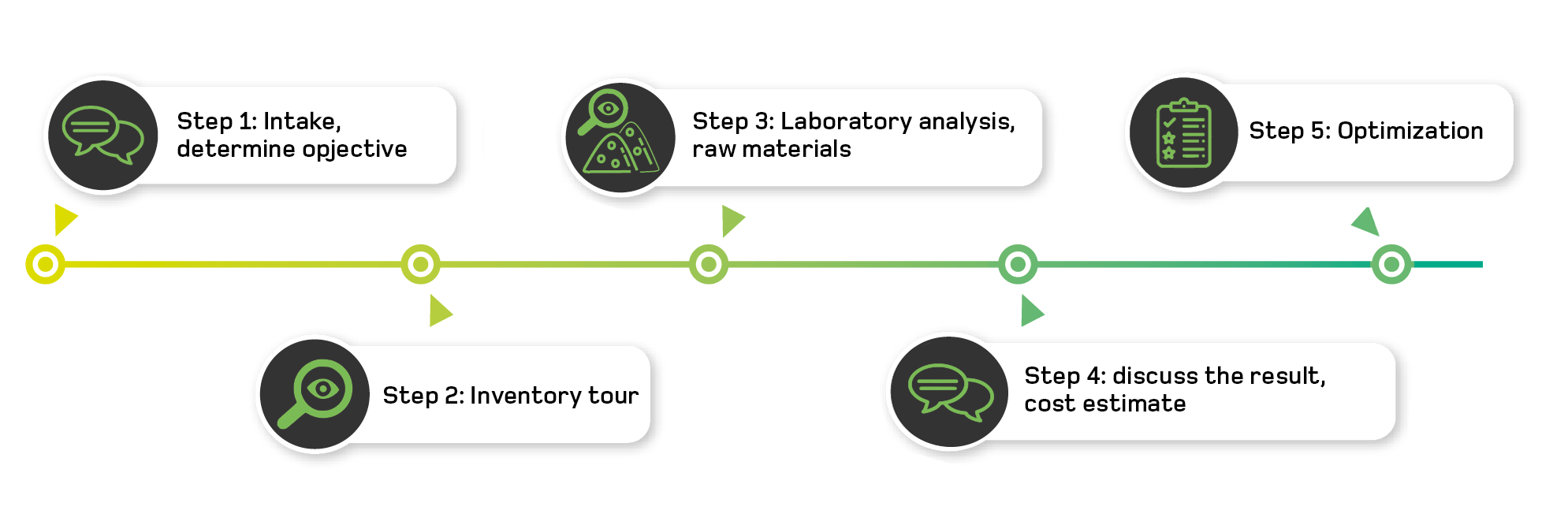

Step by Step process – Quickscan

Inventory tour – details